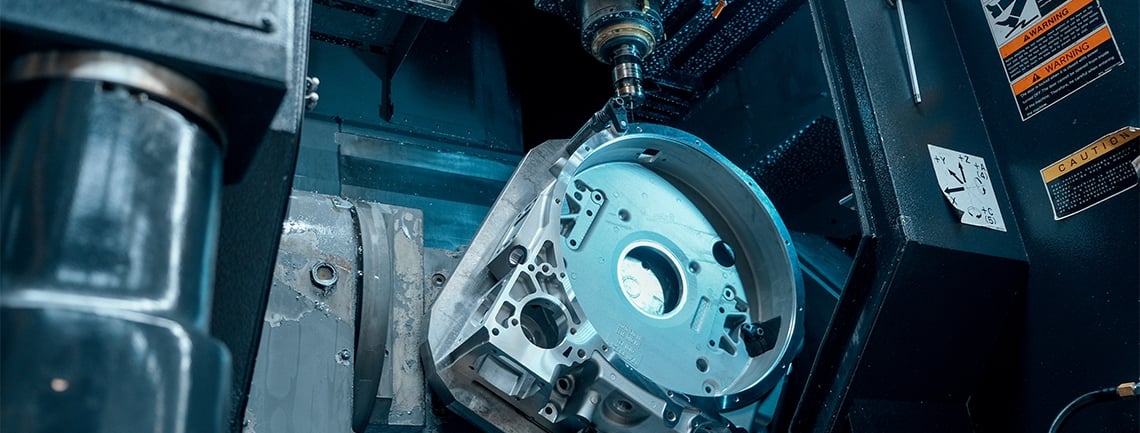

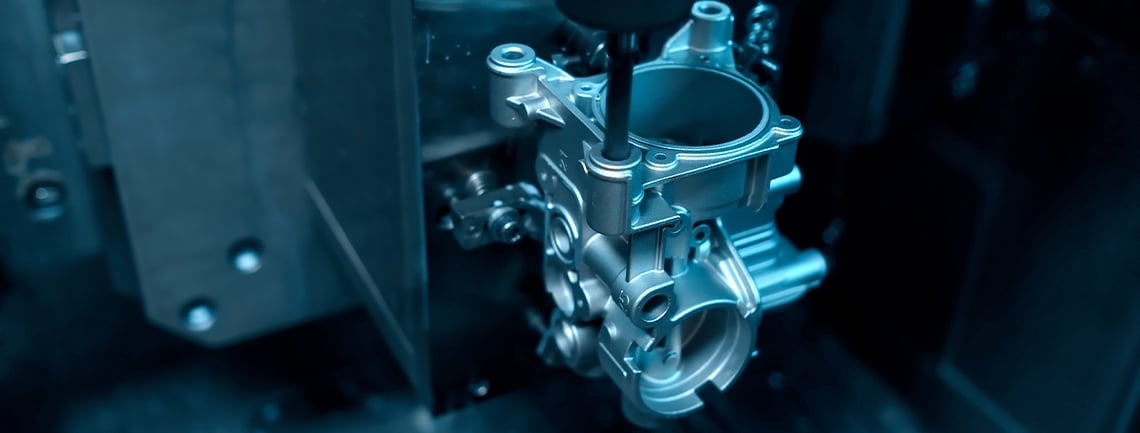

With skilled manpower, modern hydraulic fixtures, high cutting regimes and part-specific tools, production is controlled step by step and appropriate production is carried out with the understanding of minimum error and maximum quality.

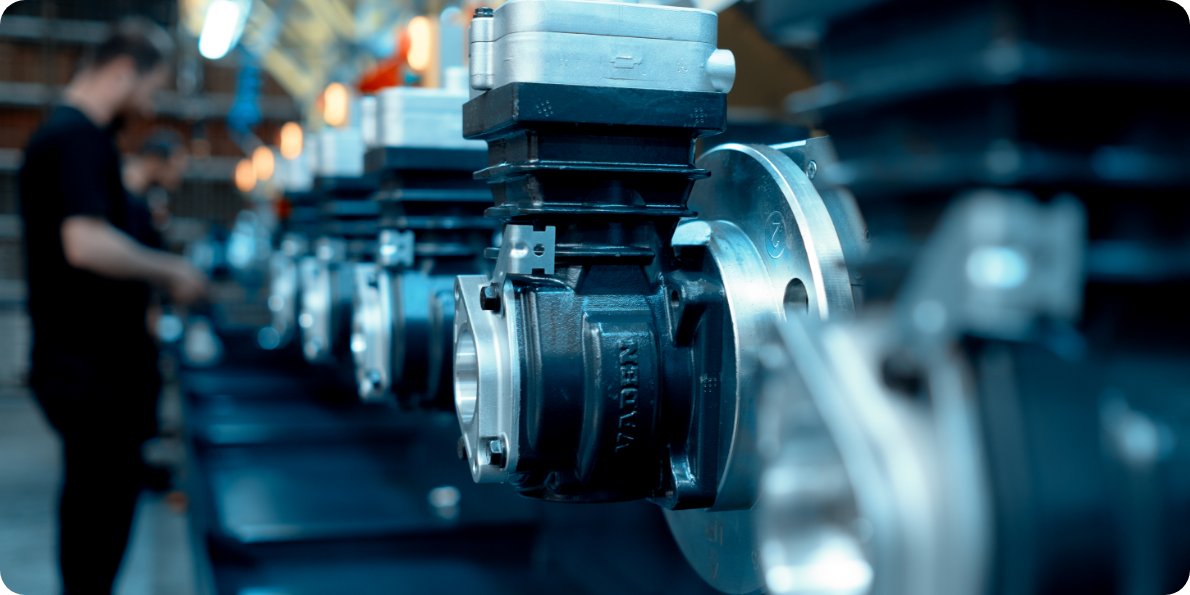

We have a young, dynamic staff with over 230 experienced engineers/technicians/ foremen and over 170 experienced operators. Thanks to our wide range of machinery and equipment, efficient production can be realized at any scale and flexibility. It has the largest and most modern machining park in its sector with approximately 295 CNC machining machines with the latest technology and high performance and over 100 other machines.

We adopt the philosophy of continuous improvement as a principle in order to minimize the unit cost per piece in the competitive environment developing in the sector and we closely follow technological developments.