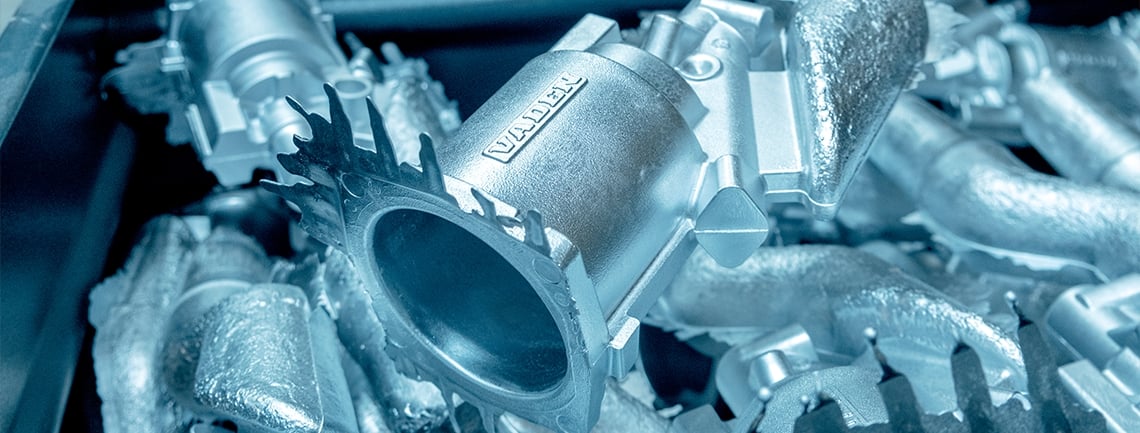

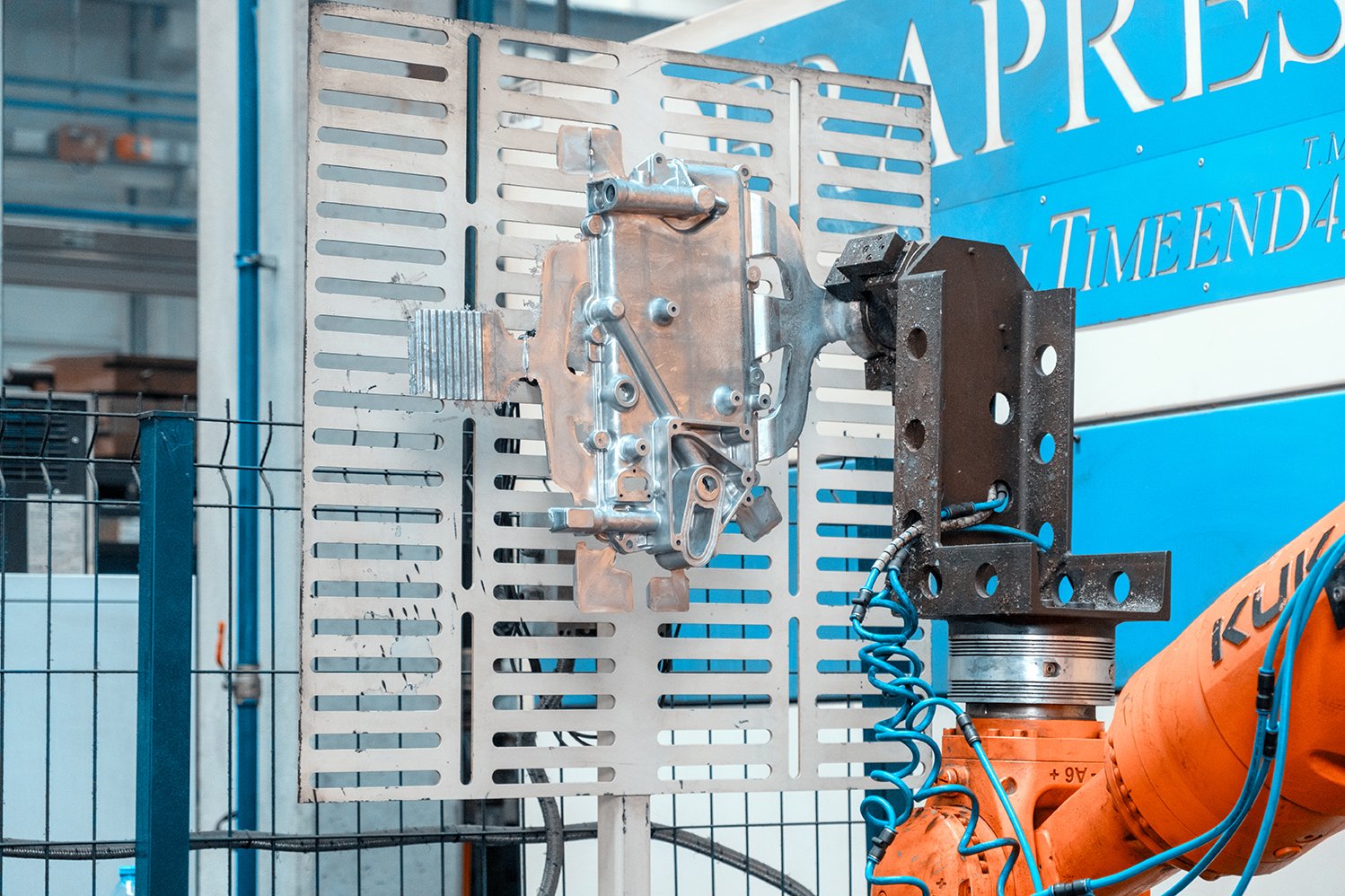

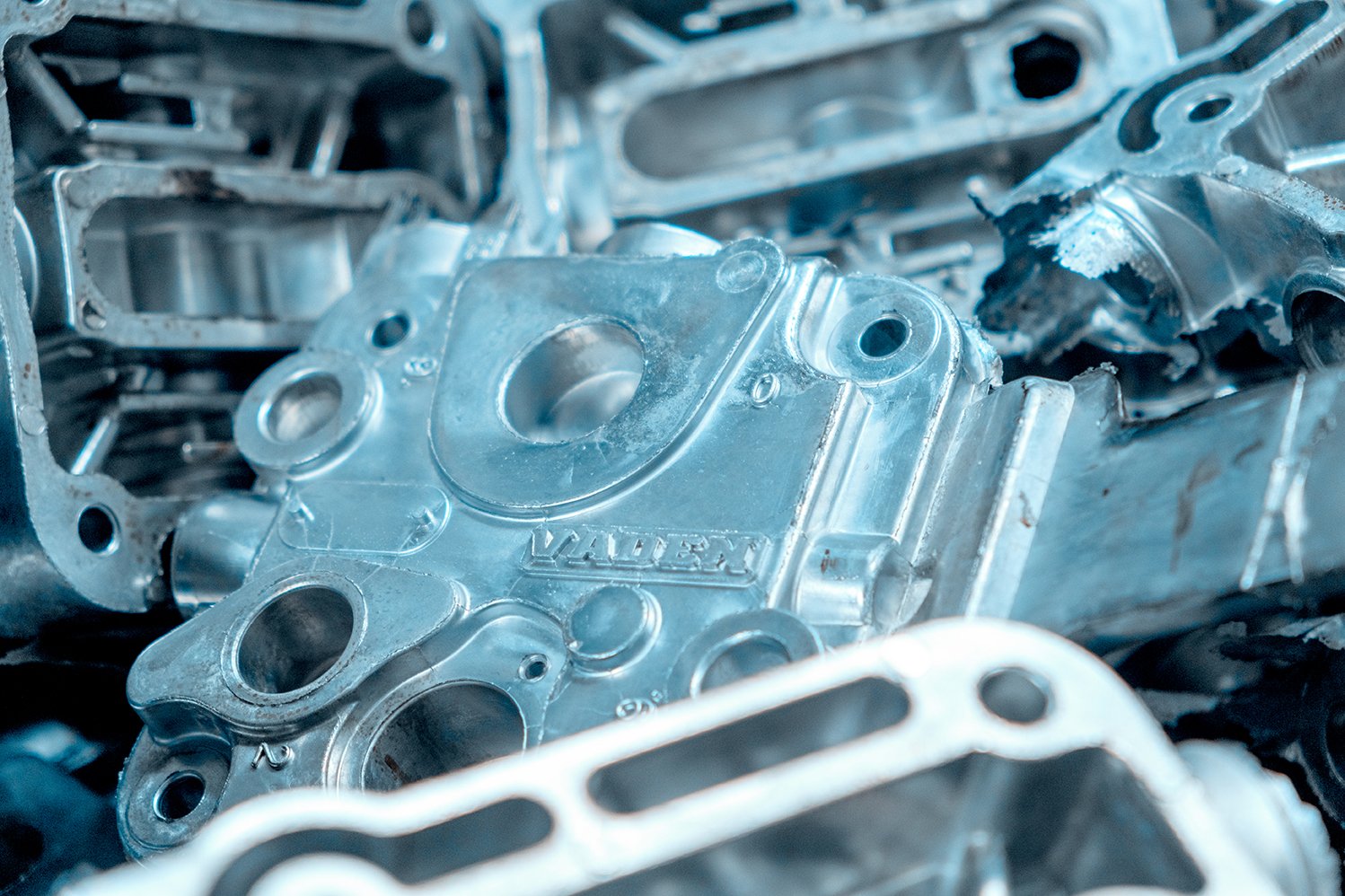

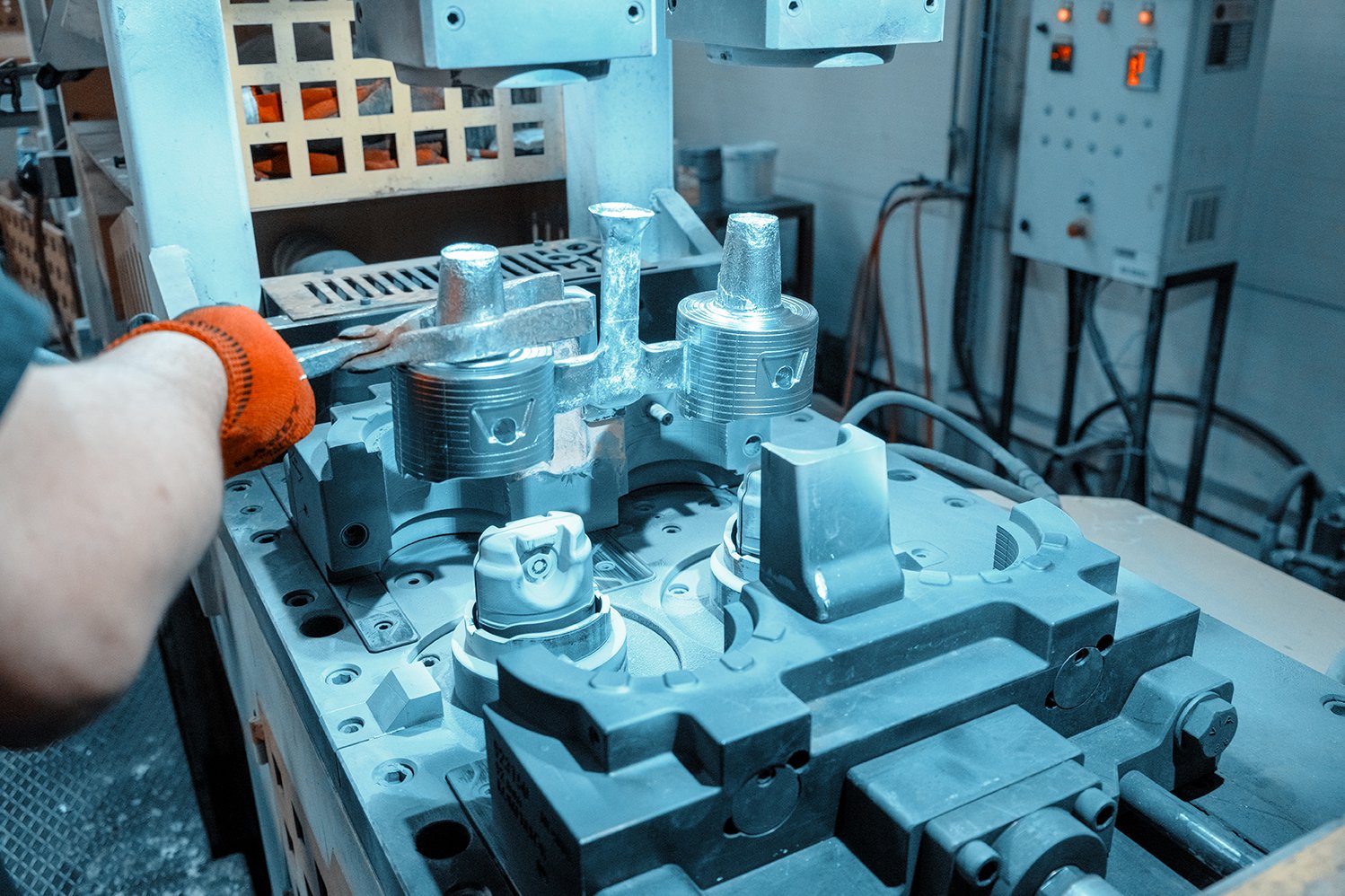

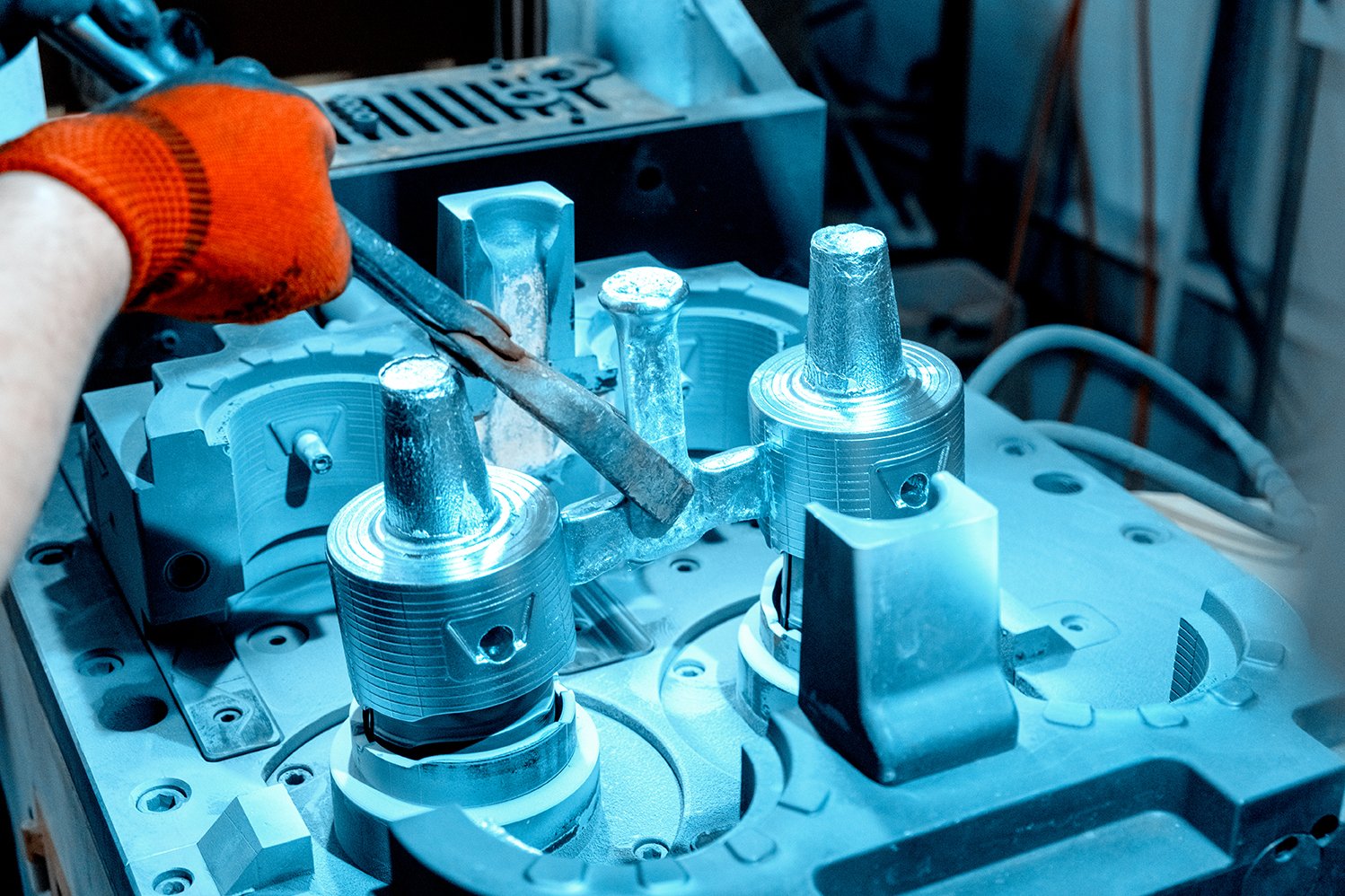

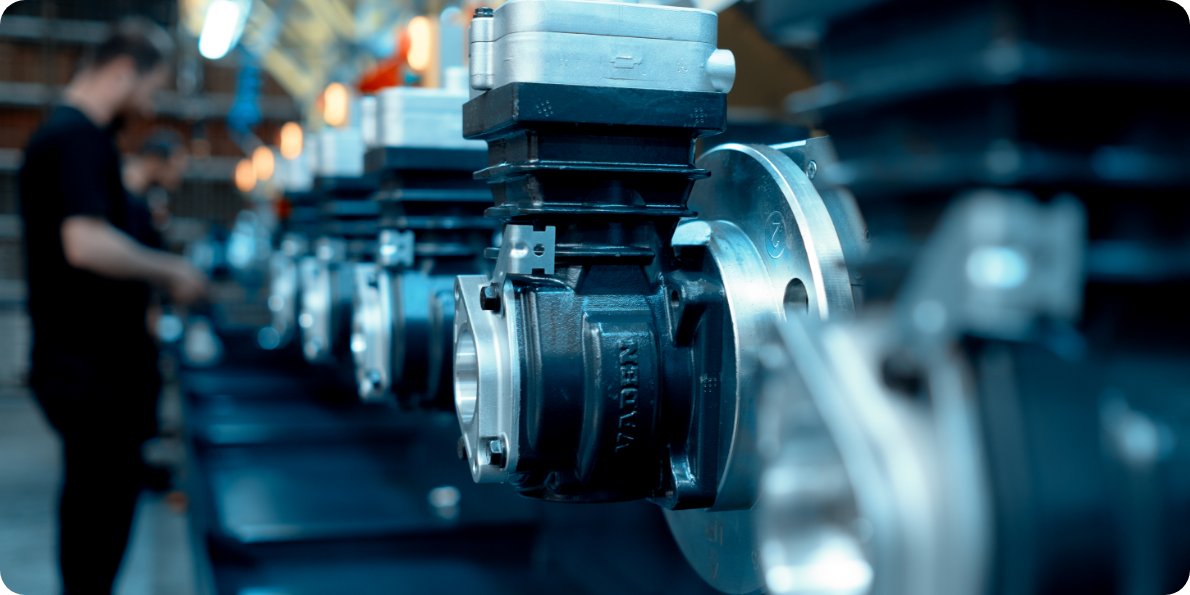

There are high pressure injection molding machines of various capacities in our Aluminum Foundry line. In our facility; There are 20 fully automated high pressure aluminum casting presses between 220 tons and 2500 tons, 17 fully automatic low pressure machines, 5 Gravity (Kokil) presses.

To meet the raw material needs of these presses, there are 5 melting furnaces with 1500/3000 kg melting capacity and the melting capacity of the presses is approximately 3000 tons/year. The parts we produce are subjected to non-destructive testing with the XRAY scanning device in our laboratory.

With the Industry 4.0-Real Time feature in our high pressure aluminum casting machines, parameters such as temperature, speed and pressure are continuously controlled during casting. In our low pressure aluminum casting machines, optimization is carried out using Magma Soft software as casting simulation.